Heat Treatment Facilities to Maximize Material Properties

List of Heat Treatment Equipment

| Equipment Name | Manufacturer | Model | Units | Effective Heating Zone (mm) |

|---|---|---|---|---|

| Vacuum Quenching Furnace | Chugairo Industry | VF-40ⅢPR | 1 | 600x600x900 |

| Vacuum Tempering Furnace | Chugairo Industry | T-40C | 3 | 600x600x900 |

| Atmosphere Tempering Furnace | Thermal | RZ6ZT/T | 2 | 500x400x500 |

| Vacuum Gas Soft Nitriding Furnace | Chugairo Industry | VN-40 | 1 | 600x600x900 |

| Vacuum Washing Machine | Chugairo Industry | HSN-S1-D | 1 | 600x600x900 |

| Sub-Zero Equipment | Wuxi ASC | cryometal-1288H | 1 | 800x800x1200 |

Controlling Hardness, Dimensional Change, and Distortion with Cold Work Tool Steel

List of Analysis and Measurement Equipment

| Equipment Name | Manufacturer | Application |

|---|---|---|

| X-ray Metal Analyzer | Rigaku | Component Analysis |

| Rockwell Hardness Tester | Mitutoyo | Metal Hardness Measurement |

| Shore Hardness Tester | Imai Seiki | Metal Hardness Measurement |

| Micro Vickers Hardness Tester | Mitutoyo | Metal Hardness Measurement |

| Sample Cutting Machine (for Micro Vickers) | Herzog | Metal Cutting |

| Straightening Press | Masada | Metal Pressing |

Technical Exchange with Japan

At Yamaichi Special Steel Vietnam, we conduct technical exchanges by inviting engineers from our headquarters in Japan to improve technology and quality.

In addition, our staff are dispatched to Japan to acquire the highest level of technical skills using Japanese equipment, and upon returning, they contribute to enhancing the heat treatment quality at Yamaichi Special Steel Vietnam.

Degreasing of Cutting Oil from Mold Parts

Vacuum Cleaning

1. Cleaning Machine (Equipment Name: Solmate)

・Vacuum cleaning machine using hydrocarbon-based cleaning liquid

・Application: Capable of degreasing cutting oil from mold parts

Features of Hydrocarbon-Based Cleaning Liquid

・Compared to chlorine-based cleaning liquids, hydrocarbon-based liquids are environmentally friendly

・Less corrosive to metals and less likely to cause rust

Effects of Cleaning and Drying Under Vacuum

・Washing under vacuum increases cleaning effectiveness

・Vacuum drying reduces the likelihood of leaving stains from the cleaning liquid after drying

Heat Treatment at Yamaichi Special Steel Vietnam

Vacuum Quenching & Tempering

2. Vacuum Quenching Furnace (Equipment Name: VQ Furnace) Operating Temperature: 1020℃ / Size 600×600×900

・Quenching furnace capable of operating under vacuum from heating to cooling

・Cooling method: N2 gas cooling

・Mainly used for special steel heat treatment due to N2 gas cooling

*Products requiring oil quenching, such as carbon steel, cannot be processed here

・Maximum cooling pressure: 5.2 bar

Features of the Vacuum Quenching Furnace

・Heating in vacuum and cooling with inert nitrogen gas minimizes surface oxidation and decarburization of treated products

*Decarburization: A phenomenon where carbon, which provides hardness, escapes from the steel surface as carbon dioxide, etc.

・Minimal decarburization results in reduced dimensional change and improved wear resistance

3. Vacuum Tempering Furnace (Equipment Name: VT1.2.3) / Size 600×600×900

・Tempering furnace capable of operating under vacuum from heating to cooling

*VT1.2.3: Operating temperature range 180℃ – 650℃ (MAX 700℃)

Features of the Vacuum Tempering Furnace

・Minimizes surface oxidation

4. Atmosphere Tempering Furnace (Equipment Name: ATS1.2) / Size 500×400×500

・Tempering furnace operating in atmospheric conditions

*ATS1.2: Operating temperature range 150℃ – 650℃

Features of the Atmosphere Tempering Furnace

・Although compact in size, cooling is performed separately after removal from the furnace once tempering is complete, allowing for higher throughput

Applicable Materials (Processing Record)

SKD11, SLD, QC11, DC11, KD11, SLD-MAGIC, SLD-F, DC53, KD11S, DCMX, QCM8,

SXACE, KD11MAX, NOGA, YAG300 (aging treatment only)

P20, STAVAX, HPM31, HPM38, 2083, S-STAR, SUS420J2, SUS440C, SUS630 (precipitation treatment only)

SKD61, DAC, F-DAC, DAC-i, DAC3, DAC-MAGIC, DHA1, DHA1-A, DHA21, DHA-WORLD,

DHA-Thermo, DH31-EX, DH31-S, ORVAR-S, ORVAR-2M, KDAHP1, KDMAX, QDH, DURO-N1

*Please contact us for other materials.

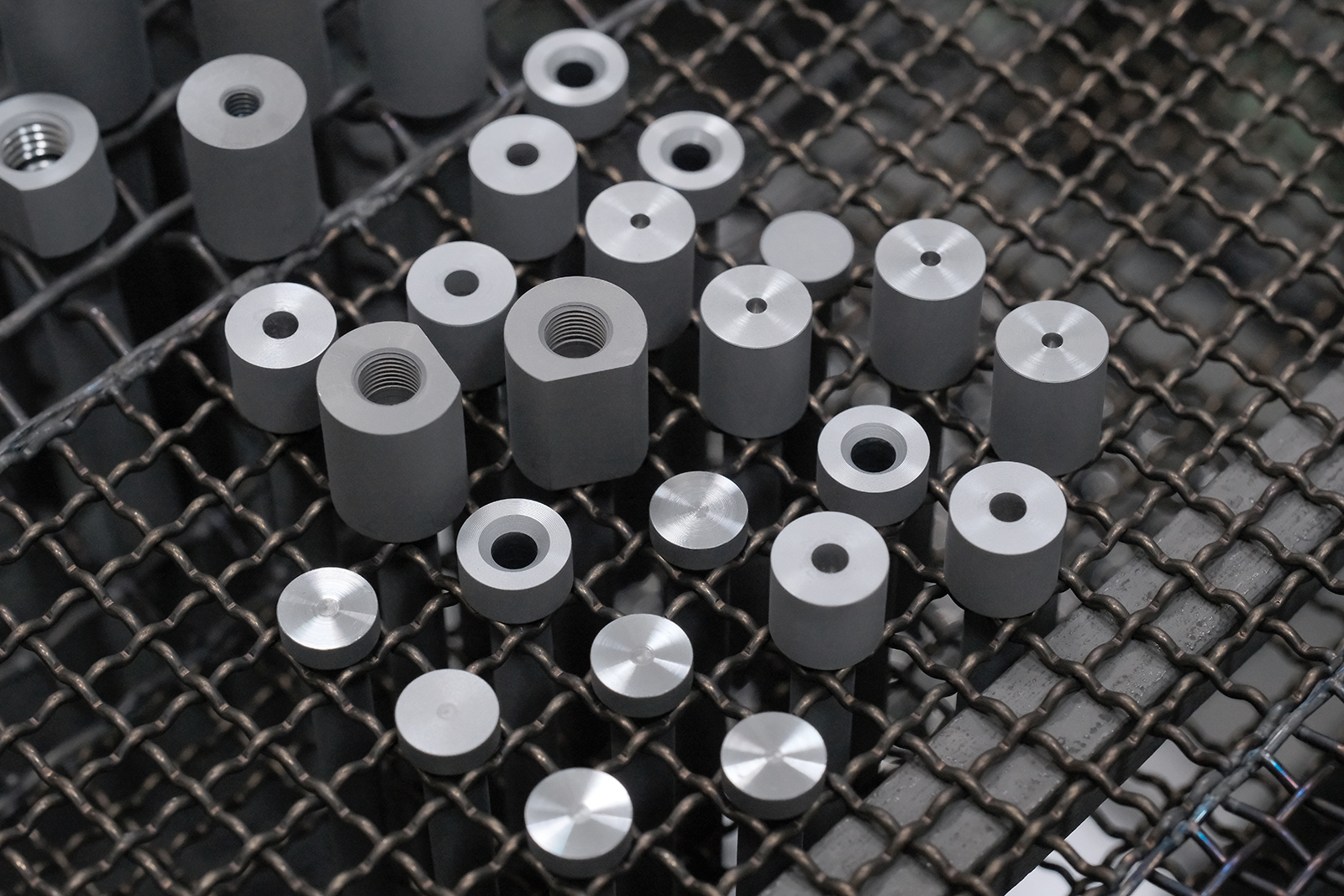

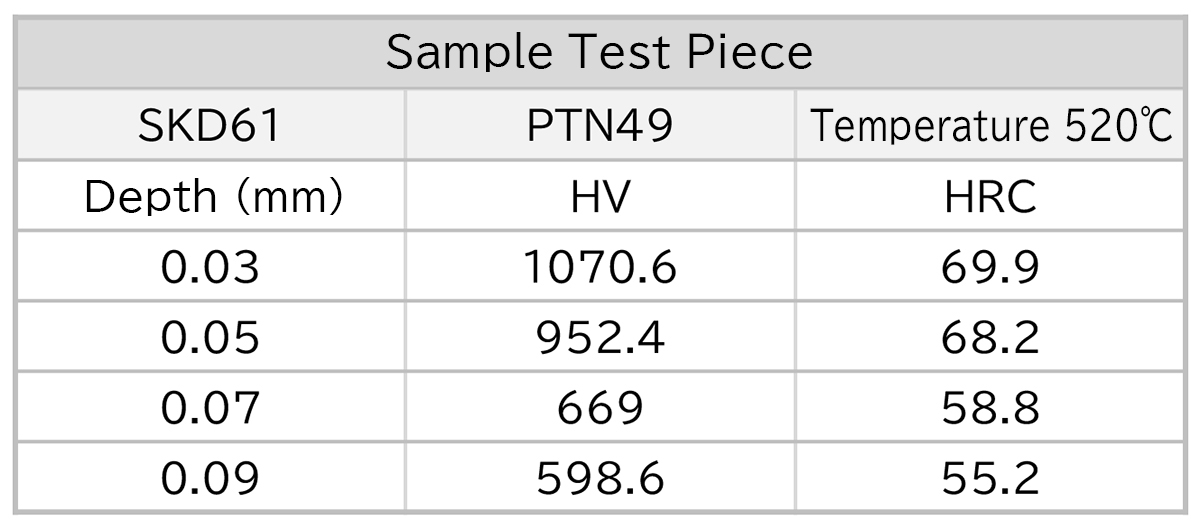

Nitriding Treatment to Enhance the Hardness of Steel Products

Gas Soft Nitriding

5. Nitriding Furnace (Equipment Name: VN-40) / Size 600×600×900

・Equipment for performing gas soft nitriding

*Operating gases: Ammonia (NH3), Carbon dioxide (CO2), Nitrogen (N2)

What is Gas Soft Nitriding?

The furnace is filled with the above gases to diffuse nitrogen and carbon into the surface of the product.

This creates a high-hardness compound layer on the surface.

Below the compound layer, a diffusion layer forms, which contributes to improved fatigue strength.

Features of Gas Soft Nitriding

Excellent in wear resistance and corrosion resistance, contributing to extended die life

6. Shot Peening

Purpose of Use at YSV

・Used as surface preparation for nitriding

By projecting alumina particles onto the surface of the product, surface irregularities are created, making it easier for gases to penetrate during gas soft nitriding treatment

Applicable Materials (Processing Record)

S45C, SKD61, DAC, H13, DAC10, DAC-MAGIC, HPM1, HPM7, S-STAR, SCM440,

DH2F, DH31-EX, NAK55, NAK80, P20,

YSM1, DHA-WORLD, DHA-Thermo

*Please contact us for other materials.

Highly Effective “Sub-Zero Treatment” Against Aging Changes

Sub-Zero Treatment

7. Sub-Zero Equipment

・Process: Quenching → Sub-Zero → Tempering

・Capable of treatments from standard -70℃ sub-zero processing to -140℃ cryogenic treatment

Effects of Sub-Zero Treatment

・Rapid cooling of quenched products transforms retained austenite into martensite

Retained austenite is an unstable structure that changes over time,

commonly referred to as “aging change.”

Sub-zero treatment is considered highly effective as a countermeasure against such changes.

*Sub-zero treatment is generally not applied to hot-work tool steels due to their high tempering temperatures

Applicable Materials (Processing Record)

SKD11, SLD, SLD-M, SLD-F, DC53, DCMX, DRS-40N, HPM31

*Please contact us for other materials.

Details of Heat Treatment Equipment

| Equipment Name | Manufacturer | Model | Units | Effective Heating Zone (mm) |

|---|---|---|---|---|

| Vacuum Quenching Furnace | Chugairo Industry | VF-40ⅢPR | 1 | 600x600x900 |

| Equipment Name | Manufacturer | Model | Units | Effective Heating Zone (mm) |

|---|---|---|---|---|

| Vacuum Tempering Furnace | Chugairo Industry | T-40C | 3 | 600x600x900 |

| Equipment Name | Manufacturer | Model | Units | Effective Heating Zone (mm) |

|---|---|---|---|---|

| Atmosphere Tempering Furnace | Thermal | RZ6ZT/T | 2 | 500x400x500 |

| Equipment Name | Manufacturer | Model | Units | Effective Heating Zone (mm) |

|---|---|---|---|---|

| Vacuum Washing Machine | Chugairo Industry | HSN-S1-D | 1 | 600x600x900 |

| Equipment Name | Manufacturer | Model | Units | Effective Heating Zone (mm) |

|---|---|---|---|---|

| Vacuum Gas Soft Nitriding Furnace | Chugairo Industry | VN-40 | 1 | 600x600x900 |

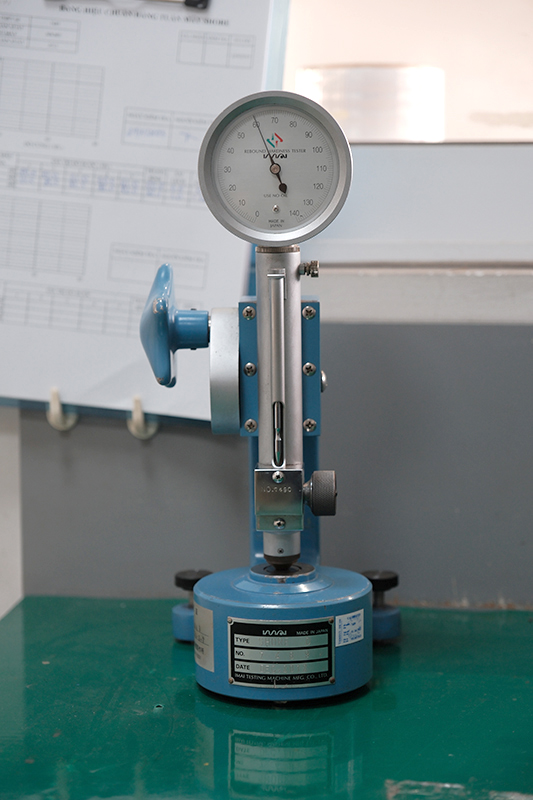

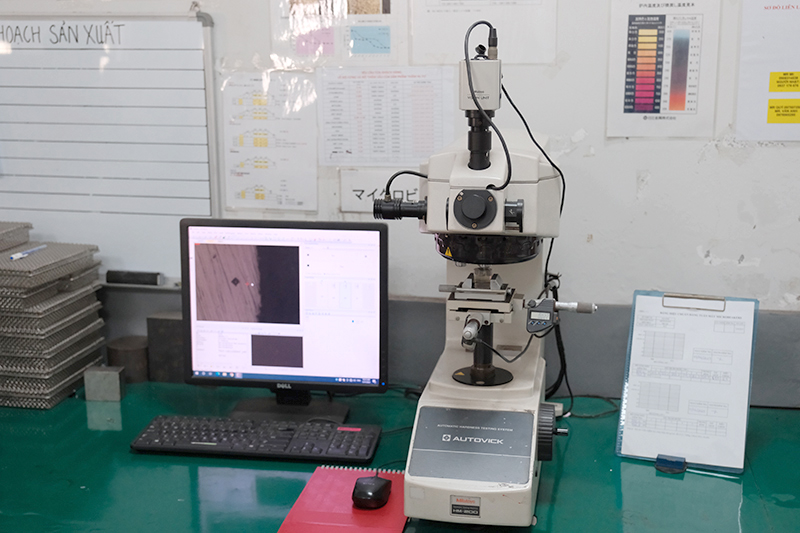

Details of Analysis & Measurement Equipment

| Equipment Name | Manufacturer | Application |

|---|---|---|

| X-ray Metal Analyzer | Rigaku | Component Analysis |

| Equipment Name | Manufacturer | Application |

|---|---|---|

| Rockwell Hardness Tester | Mitutoyo | Metal Hardness Measurement |

| Equipment Name | Manufacturer | Application |

|---|---|---|

| Shore Hardness Tester | Imai Seiki | Metal Hardness Measurement |

| Equipment Name | Manufacturer | Application |

|---|---|---|

| Micro Vickers Hardness Tester | Mitutoyo | Metal Hardness Measurement |

| Equipment Name | Manufacturer | Application |

|---|---|---|

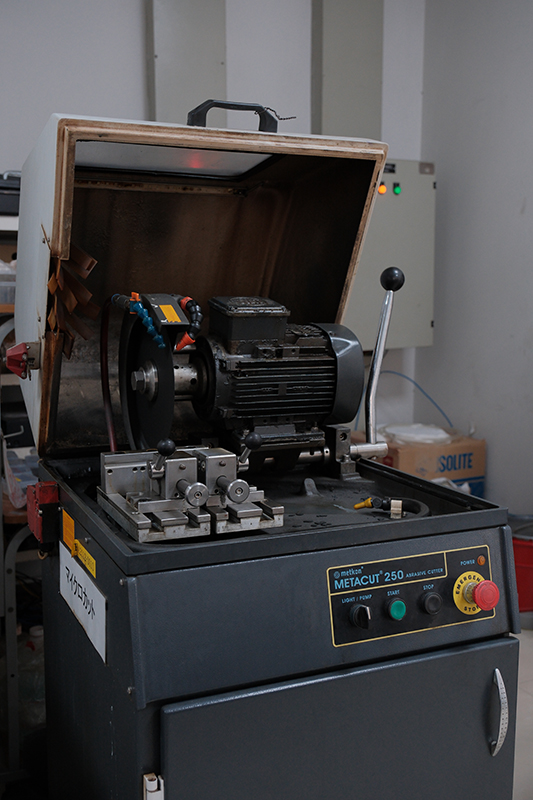

| Sample Cutting Machine (for Micro Vickers) | Herzog | Metal Cutting |

| Equipment Name | Manufacturer | Application |

|---|---|---|

| Straightening Press | Masada | Metal Pressing |